FRP. pressure pipes are flexible composite pipes built up from a thermosetting chemical resistant resin with glass fiber reinforcement.

The pipes are produced on a continuous winding helical pipe winder where all material application are synchronized in order to give uniform pipe properties.

The standards pipes are design based on ASTM D-2996 Standard Specification for Filament-Wound “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and ASTM D 2992.Obtaining hydrostatic design basis for reinforced thermosetting resin pipe and fittings. Dimensions and classification by DIN 16965.

TECHNICAL INFORMATION

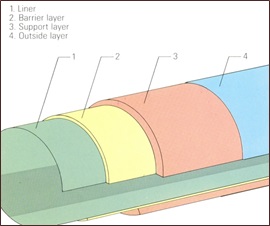

Typical Filament Wound Pipe Construction

(1). Inner surface: 10-to 20-mil resin-richinner liner reinforced with C glass surfacing mat or organic veiling.

(2). Barrier layer: Generally consisting of at least two layers of 450g/m2 chopped strand mat reinforcement.

(3). Supporting layer: Varies with the laminate strength required; may be additional 4S0g/m2 mat reinforcement, cloth, or woven roving. In heavy construction requiring more than one layer of woven roving 600g/m2 is used between layers of chipped strand mat.

(4). Outside layer: Resin-rich surface reinforced with C glass surfacing mat plus an ultraviolet inhibitor.